Introduction

I always wanted a princess seamed dress or overblouse. Now that I have fulfilled the realization of my idea I have to say that it did not fulfill all my expectations. It did turn into a good learning experience about fit, style lines and individual body shapes.

Photos of the Jumper

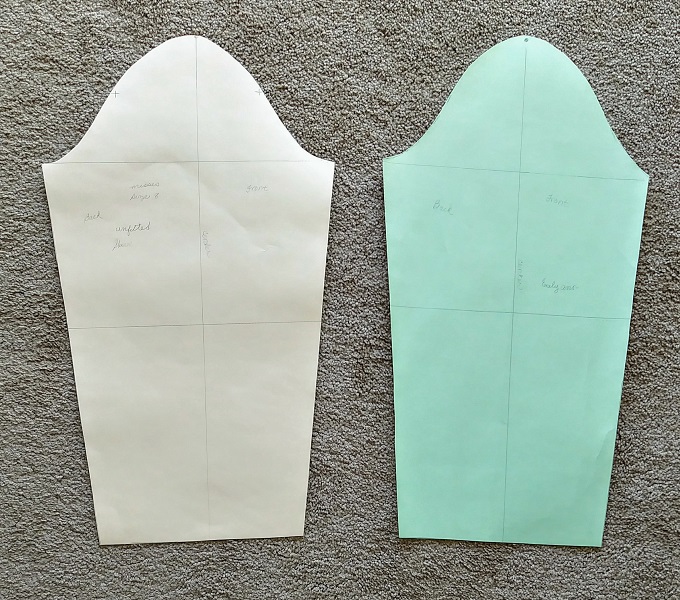

Background of the pattern

The pattern was based on the Misses Size 8 sloper developed using the Precision Draping technique created by Nellie Weymouth Link. The technique is detailed in a reprint of the 1947 book through Amazon and other booksellers online.

I altered the pattern after fitting the toile on myself and making adjustments.

Expectations vs. Reality

Originally I envisioned the princess seam over my bustline to be very flattering. Once it was finished I did not care for the look on myself.

I have sloping shoulders. This causes the apex of my bustline to be lower than a standard size. The result is that the princess seam curves a bit lower, emphasizing both my bustline and narrow, sloping shoulders. I straightened the curve on the pattern, but that did not make much difference.

I offer this experience as a way for others to learn what makes the most flattering fit for their own body type.

I love the flared skirt of the jumper, the neckline and the armholes. If I were to make this again I would use a vertical dart below the bust or perhaps two French darts in the side seam of the bodice front.

Sewing Techniques

The jumper is made from 100% cotton chambray I ordered from Mood Fabrics. The underlining is cotton batiste.

I underlined the bodice. The skirt was underlined from waist to a few inches below the waistline. I wanted the fabric to have less transparency. The underlining also served as an anchor to the zipper.

Hidden Zipper: A 1960s Couture Technique

I used the instructions for the hidden zipper sewing technique detailed in Couture Sewing by Claire Shaeffer.

The zipper must be sewn to garment pieces that are underlined. This is because the finished seam is anchored to the underlining with catch stitches or fell stitches.

The resulting zipper is a little like an invisible zipper but less rigid.

Seam Finishes

I cut the seams wider than usual because the fabric frayed. Edges were pinked and zig-zagged for durability.

Other Finishes

The all-in-one facing and hemline were finished with Wright’s Flexi-Lace. I used the Flexi-Lace for the waistline stay, too.

You must be logged in to post a comment.